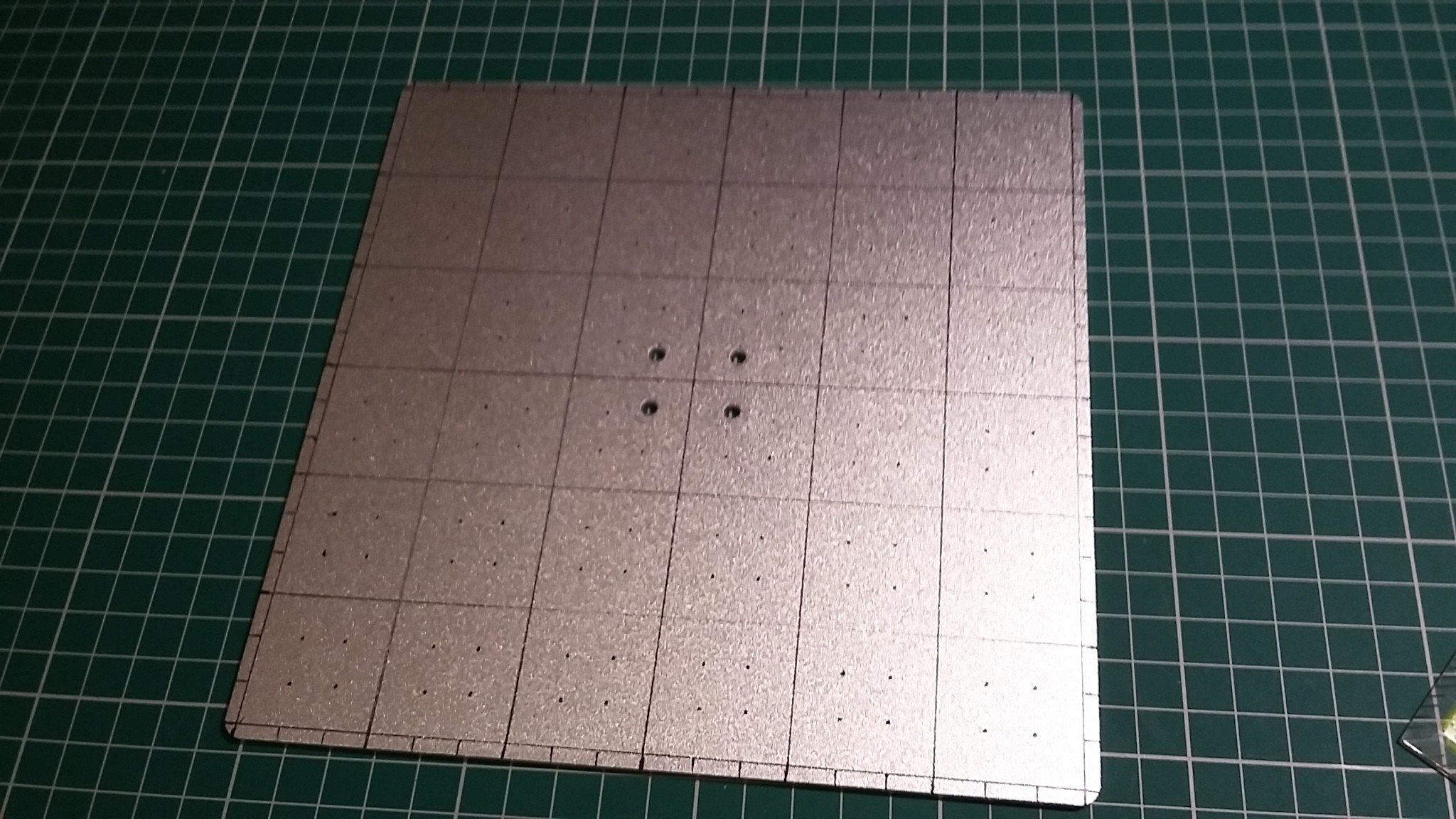

And that would be the area of the mat if you use one. It certainly needs to be within a few thousandths over the print area. Leveling refers to making the build plate as perpendicular to the vertical axis of the printer as possible. I suspect that ALL 3D printers DO need to be leveled. Did some research and looks like PEI would be the way to go. I haven't checked the flatness of the several plates that I have, but I suspect that it may vary so different shims may be needed for different plates.Īlmost forgot, my printer is not in an enclosure but is in a warm office with little air movement.I've not heard about BuildTak or PEI. I did the math and wound up with two thicknesses at one of the screw locations, one thickness at two others and none at the fourth.

PS: I used aluminum foil for the shims between the plate and the mounting surface that it screws down to. Their instructions and other information leaves a LOT to be desired. I haven't had any more failures since I added that shim.Ĭetus does not explain this very well. I think the Cetus allows you to enter values for these nine points so the "leveling" is accomplished in the software, but I prefer it to be physically as close as possible first. I used the readings I got at the nine points across the build plate to shim the build plate to make it physically level. So, Cetus, which claims it does not need to be leveled, has a screen/function just for that.

It's base was about 3" x 5" and one corner simply lifted off the plate.Ĭetus advertises that it's printer does not have to be leveled. I also had a failure of my first somewhat larger object to adhere to the build plate. I do have a reel of ABS and plan to use it soon. I also have a Cetus and, so far, I have only tried printing with PLA. So far the PEI seems to be working and once it has cooled down the parts are fairly easy to remove.Īlmost forgot, my printer is not in an enclosure but is in a warm office with little air movement. ABS on BuildTak was sticking almost too well, it was a bear to remove the print and the reason I ended up destroying it. Try cleaning the surface with denatured alcohol and if that doesn't do it try acetone. The first layer needs to be smashed onto the build surface, if it's not being laid down oval it will never stick.

The single most important item I discovered with any surface is bed leveling and nozzle height. This also allows me to quickly switch back and forth between the original BuildTak surface and the glass plate with PEI. I ended up using glass with PEI, printed a spacer that clips above the Z axis limit switch that raises the home position just enough to add the glass to the bed. Think heating the bed to 90 and the acetone also contributed to the destruction of the BuildTak. Problem was I ended up destroying the BuildTak removing the finished prints. General feelings are to use PEI on glass for the surface but I was able to get good adhesion on the original BuildTak surface by cleaning it with acetone. I didn't care for the idea of using tape, hair spray or glue and was determined to get it working with either BuildTak or PEI.

Just went through this with my Maker Select.

0 kommentar(er)

0 kommentar(er)